Our Factory

Our production capacity is more than 20,000 Kg per month

At FILATECH we have fully integrated and automated PLC controlled production lines in different areas to ensure about a consistent supply of high quality 3D filaments to our customers. Our production capacity is more than 20,000 Kg per month for several types and colors of ordinary and specialty filaments.

High quality 100% virgin raw material and additives

RAW MATERIAL HANDLING

High quality 100% virgin raw material and additives are handled and processed in different areas like:

1. Raw Material Storage Area

2. Weighing & Formulation Area

3. Mixing Area

4. Drying & Dehumidification Area

5. To be prepared for the next production steps.

Raw material and additives are dehumidified for the higher quality

Raw material and additives are dehumidified for the higher quality

EXTRUSION

In a continuous process, the formulated mix of raw material and additives which already dehumidified for the higher purity and quality, is preheated and extruded into the raw filament during a very precise regime of preheating, melting, homogenizing and cooling. Process is fully automated and controlled by PLC and HMI system.

Precise and accurate temperature control

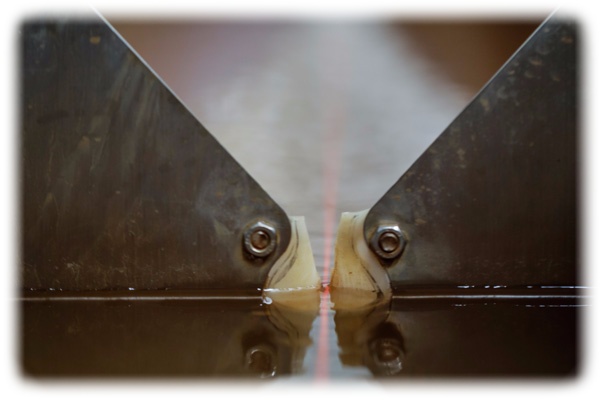

WATER HEAT TREATMENT

Precise and accurate temperature control during two stages of water heat treatment in a continuous process is essential to achieve a perfect roundness and consistent size for the filament. Every filament has its own specifically developed heat treatment curve.

Filament with precise diameter and tolerance

FILAMENT SIZING AND TOLERANCE CONTROL

A PLC controlled Hull-off machine with a multi-spool buffer is used to form the heat treated raw filament into the final filament with precise diameter and tolerance in a consistent and continuous process.

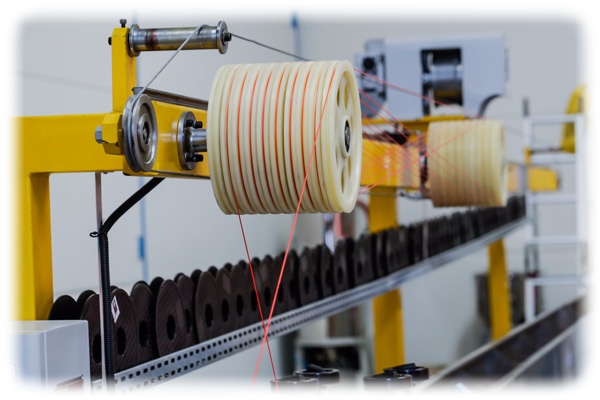

Winding machine equipped with lost-in-weight spool delivery system

WINDING

A double spool automatic PLC controlled winding machine equipped with lost-in-weight spool delivery system is winding the finished filament of spools making them ready for next stage which is vacuum shrink packaging

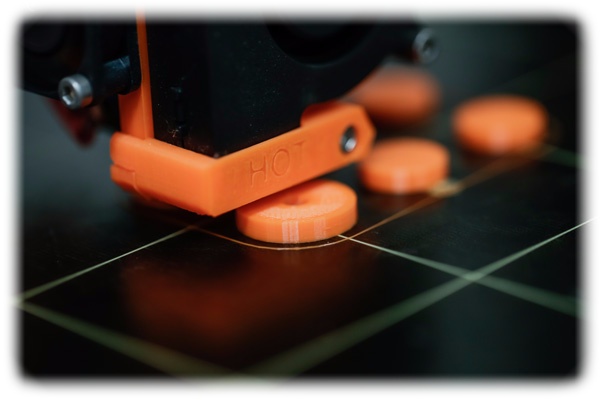

Filament quality is continuously being watched

QUALITY CONTROL

Important parameters like size and diameter tolerance, roundness, color consistency and printing quality are continuously being watched, tested and controlled thought the entire process.